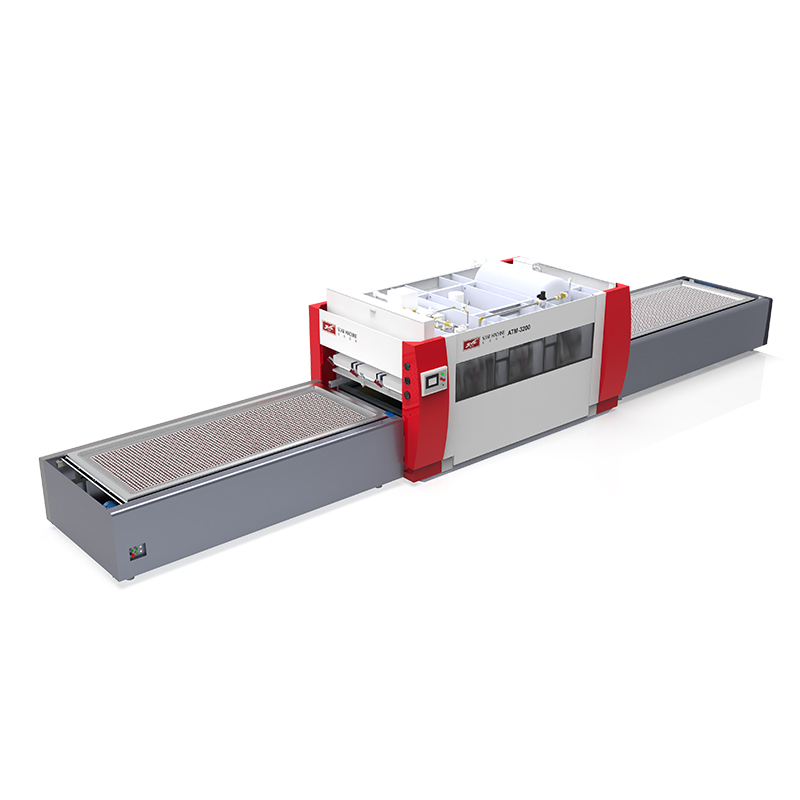

ATM-3200 Auto pin membrane ea mochine oa khatiso

Mochine oa khatiso oa membrane ea vacuum ATM-3200

E sebelisoa ho sebetsa le mefuta e fapaneng ea PVC ea boleng bo holimo, botlolo bo phahameng, phetisetso e chesang le veneer ka lehlakoreng le leng.Haholo-holo tobetsa khabinete, liaparo le thepa e 'ngoe.

Lihlahisoa ke tsa boleng bo holimo, 'me li ke ke tsa senyeha, mohala le groove li hlakile.

Mochine ona o ka khetha silicon pre-press mode (ho kenya khatello e ntle habeli ka pampiri ea rabara ea silicon) ho ntlafatsa boleng ba tlhahiso.

Mehlala

pompo ea vacuum, e sebelisang theknoloji ea Jeremane, matla a eona a lipere a matla, 'me bophelo bo bolelele ba ts'ebeletso.

Enjene e ka sehloohong ea tsamaiso ea khatello ea metsi e amohela tsamaiso ea machaba e tsoetseng pele.Molao-motheo oa plug-in oa poleiti o na le sebopeho se tsoetseng pele, tekanyo e tlaase ea ho se sebetse, ho phalla ho phahameng le khatello e potlakileng (nako ea ho hatella hoo e ka bang metsotsoana ea 5 ho e-na le nako ea ho hatella e tloaelehileng 15-20 metsotsoana) kahoo e khothalletsa tlhahiso. bokgabane.

Sistimi ea ts'ebetso e khetha lisebelisoa tsa taolo tsa "Delta" PLC tsa machaba le skrine e kholo ea mochini oa motho.Mochine o bonolo ho o laola, 'me theknoloji e tsoetse pele haholo.Degree ea othomathike e phahame haholo.

Lisebelisoa tsa mantlha tsa motlakase bakeng sa sistimi ea taolo li sebelisa "Schneider", "Weidmuller", Taiwanese "Delta", Sechaena "CHINT".

Pontšo ea nomoro ea hajoale, ponts'o ea motlakase, e bonoa habonolo.Thepa e nyenyane ea ho laola mocheso oa k'homphieutha e amoheloa ho laola mocheso hantle.

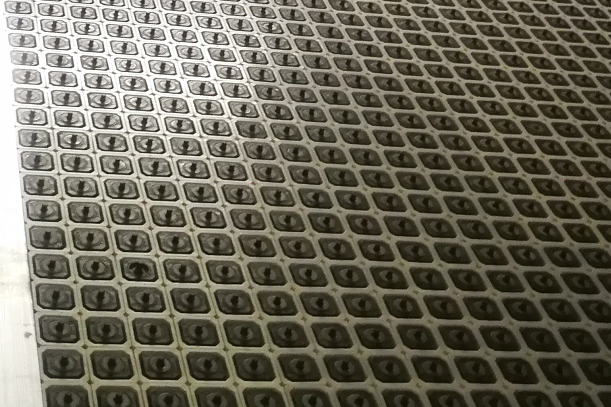

Reka ea mochini e entsoe ka lipoleiti tse 6 kaofela tsa tšepe tse chekiloeng ho qoba ho senyeha ha tjheseletsa.

Sistimi ea maeto bakeng sa motsamao oa poleiti e amohela patent ea k'hamphani ea rona, e ts'oanang le 'musisi oa maqhubu, e etsa lebelo le tlase ho qala, butle butle, lebelo le phahameng ho tsamaea, lebelo le tlase ho emisa.Etsa bonnete ba motsamao o tsitsitseng ho qoba ho fetisoa ha karolo ea mosebetsi

hlomella li-cutters tse 2 tsa othomathike, li-2 li-roller tse 8 li tšehetsa PVC, lithipa tse 2 tsa hook le lithapo tse sehang.

Lintho tse ka sehloohong tsa ATM-3000II: meralo e entsoeng ke batho

1. Meetso ea alamo bakeng sa ho se sebetse hantle lenaneong la PLC e na le botlalo.Malfunctions a hlakile ebile ho bonolo ho a rarolla.

2. Ho kenya li-sensor tsa khatello tse fapaneng tsa Jeremane, li laola ka nepo khatello e nepahetseng ea dijithale.

3. Mochini o na le mefuta e 4 (matt PVC, gloss e phahameng, veneer, silicon pre-press), re ka khetha mohlala o nepahetseng ho latela moetso o fapaneng.

4. Hlophisa lenaneo la tlhokomelo e tlamang ho PLC.

Litlhaloso tsa Tekheniki

Ka ntle boholo: 13030mm×2230 limilimithara×2150mm

Saese ea poleiti e sebetsang: 3000mm×1320mm (boholo bo ka hare)

Boholo ba boholo ba karolo ea mosebetsi: 2800X1200mm

Bophara ba filimi ea PVC bonyane 1400mm

Bophahamo bo phahameng ba karolo ea mosebetsi: 50mm

Khatello ea ho sebetsa: Khatello e ntle≤0.6Mpa

Khatello e mpe≥-0.095Mpa

Kakaretso ea Matla: 56kw

(Sistimi ea ho futhumatsa oli e kaholimo: 45kw, pompo ea vacuum: 2.2kw, sistimi ea hydraulic khatello: 5.5kw, pompo ea oli e tsamaisang mocheso: 0.5kw, enjene ea maeto: 1.1kwX2 (litafole tse peli) = 2.2kw)

Tšebeliso ea 'nete ea matla: Hoo e ka bang 13-15kw (motlakase le oli e futhumatsang e kopantsoeng le polokelo e phahameng ea matla, ha mocheso o fihla mocheso o behiloeng, o ka bolokang mocheso nako e telele, tlatsetso e latelang le ho boloka mocheso o hloka hoo e ka bang 1/3 ea matla a felletseng, pompo ea vacuum le hydraulic pressure system ha e qale ho fihlela e hlokahala)

Boima ba 'mele: 16T

Tshebetso

1. Mokhoa o qaqileng oa ho sebetsa

Ka kopo bala khaolo ena ka hloko 'me e tla u thusa ho utloisisa ts'ebetso, ts'ebetso ea ts'ebetso le litsebo tse khethehileng tsa mochini ona.E tla boela e bebofatse ts'ebetso ea hau e le hore e sebetse ka tsela e nepahetseng.

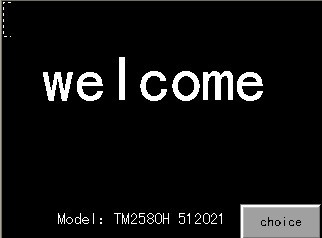

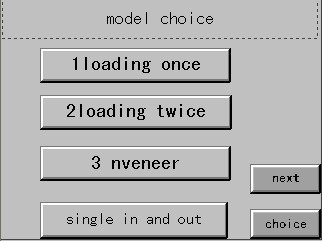

2. Bula libaka tse tharo tsa tšohanyetso, skrine ea PLC e khantša (setšoantšo sa 1).Mochini o ke ke oa sebetsa haeba e 'ngoe ea tse tharo e sa buleha.

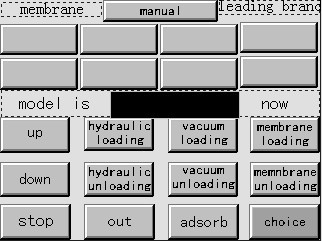

3. Tobetsa"khetho"(setšoantšo sa 2), fetola mokhoa oa ho sebetsa ho "manual"(setšoantšo sa 3)

Qala ka ho qala pompo ea Phetisetso e Chesang ho qobella Ho Fetisetsa Oli motsamaong oa potoloho, 'me metsotso e mehlano hamorao, bulela Phetoho ea ho futhumatsa.Ha shutdown e sebetsa, qala ka ho tima Heating Switch, 'me u boloke pompo ea oli e ntse e sebetsa ho fihlela metsotso e 30 hamorao, ha Oli ea Transfer e chesang e theoha, ebe pompo ea oli e ka tima.

4. Khetho ea mohlala oa ho sebetsa: F1 e kenya hang, F2 e kenya habeli,

F3 veneer ea mohlala, F4 silicone prepress

Konopo F1-F4 e ka letsohong le letona la skrine, tobetsa ha u khetha;mefuta e fapaneng e rekota ho theknoloji e fapaneng ea sehlahisoa, mocheso o fetotsoeng ka ho fetoha ha mohlala.Khetho ea mefuta e sebetsa feela maemong a 'Manual'.Ha e khone ho fetola mohlala ts'ebetsong ea othomathiki.

5. Boemo ba mocheso: mocheso oa moea o behiloe ho 100. qala boto e tlase ea ho futhumatsa ha u etsa gloss e phahameng ea pvc, ka kakaretso ke 55 ℃, ka lehlabula, ho ea ka mocheso oa ka tlung, ha ho feta 50 ℃

Mocheso o kaholimo oa board board:

e behiloeng ke mohlala o sebetsang le pvc.ha o le F1 le F2, Beha 135℃ bakeng sa gloss e bataletseng pvc, 100℃ bakeng sa pvc e khanyang e phahameng;ha F3, 120 ℃ sete bakeng sa lihlahisoa tsa veneer;ha e le F4, 85 ℃ e behiloe bakeng sa pvc e khanyang e phahameng.

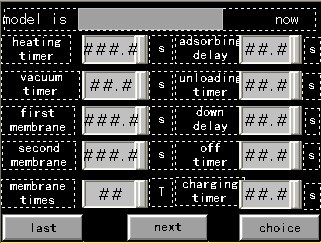

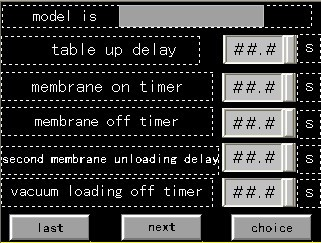

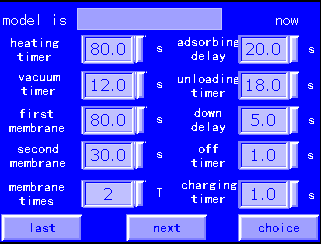

6. Boemo ba parameter

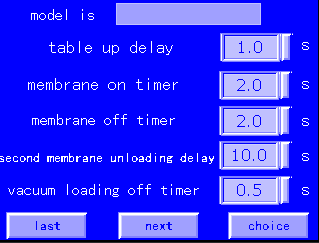

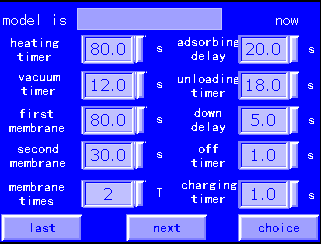

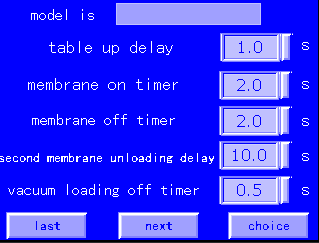

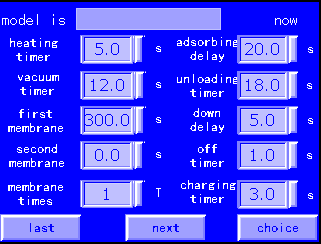

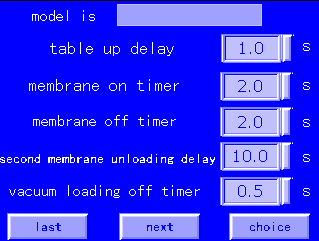

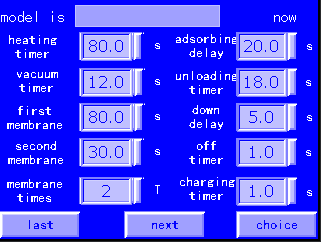

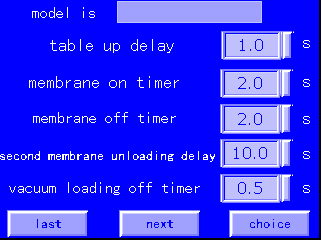

khetha "khetho" ho "setting ea parameter", joalo ka setšoantšo sa 4. Pele o khethile mohlala oa ho sebetsa, joale ka mor'a moo, fumana setšoantšo sa parameter setting (setšoantšo sa 5 le 6).Tlhokomeliso, lipalo tse peli li tlameha ho behoa ka bobeli, li se ke tsa lebaloa.

Paramethara ea motheo e behiloeng e lateloa bakeng sa ho buuoa, ho tla ba le phetoho e itseng ha ho sebetsa.Beha 0.45mm high gloss pvc e le sampole

F1 parameter ea mohlala

F2 parameter ea mohlala

F3 parameter ea mohlala

F4 parameter ea mohlala

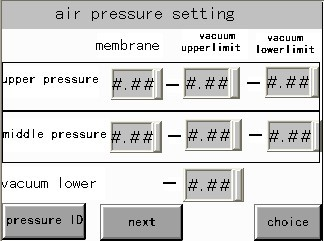

sete ea khatello ea ho sebetsa:

Khatello ea Membrane e behiloe 0.6MPA bakeng sa max, e hanetsoeng ho kenya.

7. Ts'ebetso ea matsoho ka kakaretso e sebetsa bakeng sa preheat tafole e sebetsang, e khethile "khetho" ho "manual" ka palo ea pele.Setšoantšong sa "manual", tobetsa "adsorb", rabara ea silicone e adsorbed bakeng sa ho futhumatsa.Tobetsa konopo ea "tafole e ka holimo", tafole e ka holimo e tla tsamaea ka lebelo le phahameng, metsotsoana ea 8 hamorao, e tla lieha ebe e emisa ha e ama mochine oa moeli.Tobetsa "holimo", tafole ea ho sebetsa e tla phahamisoa, 'me silicone e tla oela fatše.Ha u fihla "table upper limit", tobetsa "hydraulic load", e tla emisa ha e fihla "hydraulic low limit" le "hydraulic upper limit".qala "vacuum load" ebe joale "membrane load".Tobetsa "membrane unload", ebe "vacuum unload", ha bobeli ba tsona e le 0, tobetsa "hydraulic unload", nka metsotsoana e 5 bakeng sa ho laolla ka ho hlaka.Ebe o ka tobetsa "down", 'me enjene ea hydraulic e sebetsa feela metsotsoana e 3 ts'ebetsong ena.Ha tafole touch limit limit switch, tobetsa "out", tafole e tla tsamaea ka lebelo le phahameng, hape le 8s hamorao, fokotsa lebelo ebe u emisa.

8. Ts'ebetso ea boiketsetso:

Pele o khethile mohlala o sebetsang, ebe leqephe le latelang, beha litekanyo tsohle, le khatello ea ho sebetsa.Tobetsa "adsorb" ho futhumatsa letlapa la silicone bakeng sa metsotso e 5.Ebe u qala tafole, mochini o tla sebetsa joalo ka paramente e behiloeng, 'me u ntše tafole ha o qetile.